About Us

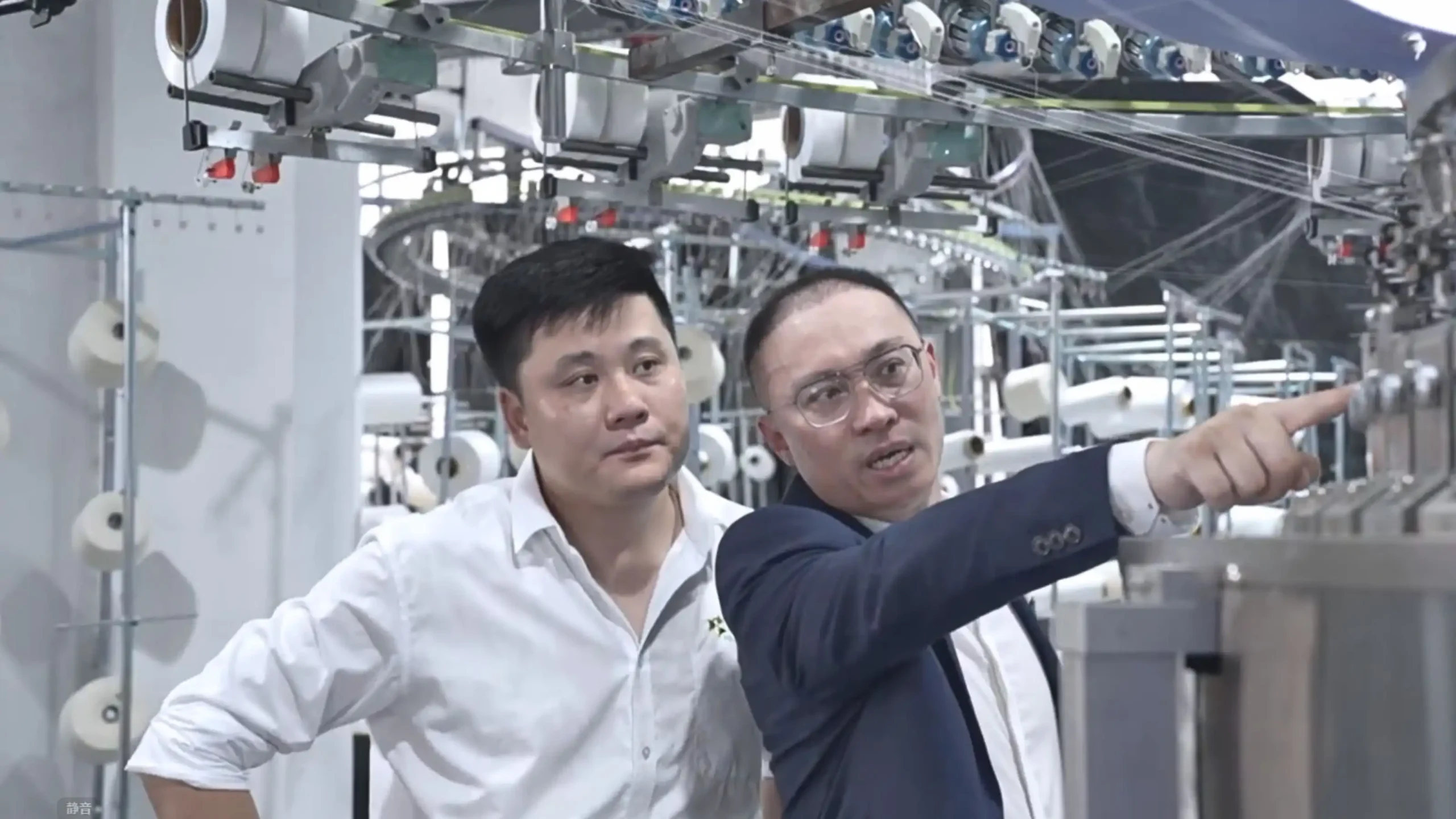

Mr. Huang

Founder & Director

Mr. Fu

Marketing & Partnership

Beatrice Carpenter

Finance & Legal

Terry Banks

Support & Care

Our Corporate Culture

Care for Employees

We are committed to providing a stable corporate platform for our employees’ growth, aiming for sustainable development where both our people and the company thrive together. We strive to create an environment of happy and dedicated work.

Customer Value Creation

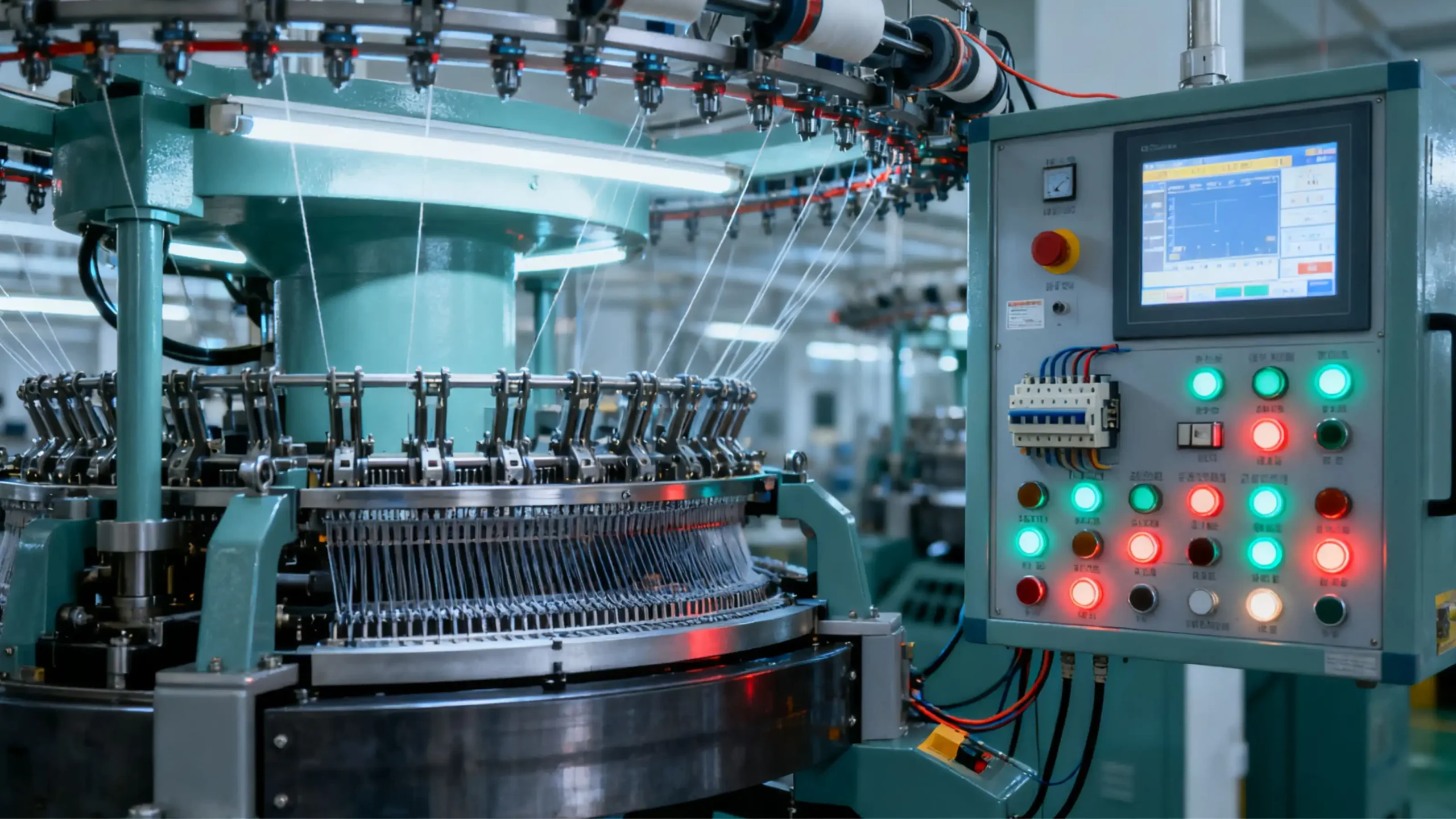

Our mission is to provide high-precision, stable, and reliable circular knitting machinery, continuously creating value for our customers. We dare to scale new technological heights, turning the impossible into reality, and enabling our clients to experience supremely reliable, stable, and fully customizable solutions.

Environmental Responsibility

We deepen our commitment to environmental stewardship by continually exploring new materials and manufacturing processes. We are dedicated to energy-saving, emission reduction, and low-carbon operations, contributing to sustainable industrial development.

Collaborative Win-Win

We constantly deepen close cooperation with our upstream and downstream supply chain partners, adhering to a community of shared future. We strive to create a “Blue Ocean” of innovation in the field of machinery manufacturing and processing, contributing to the healthy development of our industry.

Why Choose Our Manufacturing Power?

Direct Factory Prices: Save up to 30%

Technical Expertise

50+ partners worldwide

Guaranteed compliance with international quality

Our Story

Origins: The Fusion of Craftsmanship and Vision

Established in 2013 in Quanzhou, a key manufacturing hub in China, Quanzhou Vilike Machinery Industry & Trade Co., Ltd. was born from a professional team with over a decade of deep expertise in circular knitting machine manufacturing. Driven by a passion for technology and market insight, we set out to build a machinery brand driven by innovation and defined by quality

Our Core: Expert Team and Precision Manufacturing

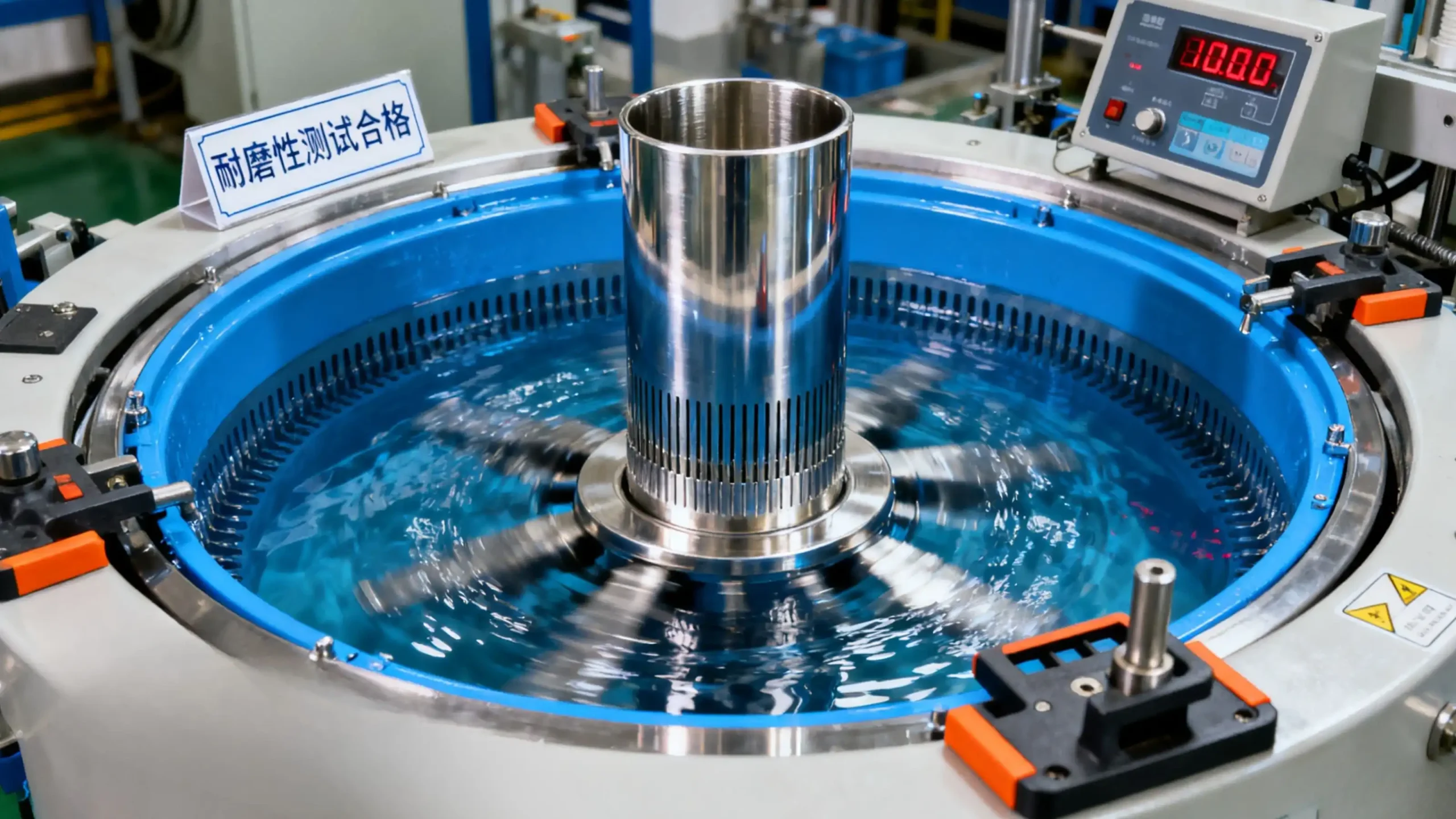

Vilike’s strength lies in our professional team and advanced manufacturing capabilities. Our team possesses comprehensive expertise spanning design, R&D, and production. Equipped with precision CNC machine tools, including CNC lathes, machining centers, and grinding machines, we ensure that key components—particularly the knitting heads made from aircraft-grade aluminum alloy or high-quality German alloy steel—achieve extreme precision, laying a solid foundation for the long-term stable operation of our machines

Our Pursuit: Innovative Design and Global Quality

We firmly believe innovation is the engine of progress. Vilike boasts over 100 circular knitting machine designs with intellectual property rights, continuously meeting diverse global market demands. In quality control, we integrate manufacturing standards from Germany, Japan, and China. Guided by modern industrial design principles, we strive for perfection in details like operational experience and surface treatment, all aimed at delivering products that excel in both sensory appeal and performance

Our Reach: A Bridge Connecting China and the World

Since our inception, Vilike’s products have been exported to markets including Europe, Japan, the USA, South Korea, Turkey, Middle Eastern countries, and China. Our annual output of 200 to 300 units signifies our commitment to the market. We are more than just equipment suppliers; we are reliable partners in our customers’ technological upgrade journeys.

Our Promise: Weaving the Future Together

Looking ahead, Vilike remains committed to our philosophy of “Master Craftsmanship, Led by Innovation.” We look forward to collaborating with textile producers worldwide, using our reliable and efficient circular knitting machines to help weave a broader and more brilliant future for the industry.

Factory Introduction

We have more than 3000m2 square meters of standard workshop, office space and employee dormitory. Garden ‘s actlvity area and 5S management system be applied to production process to ensure each machine is manufactured according to the uniform quality standards.

Company administratlon bullding organized AdmInistratlon& Financial department、Design room、Production department、Purchase department、 Staff Restaurant 、Bussiness conference room and Other duty department. We try our best to construct new model bussiness negotiation and leisure activities. Campaign of enterprise and products culture on whole admInlstratlon Bullding by vldeos and photoes. Its brIng all customers experience belief what we created“SEIKO QUALITY、 POWER UNCOMMON” .

Our Journey Through Time

2022

In 2022, we will continue to expand the production ability, select the personnel of the core team, and improve the production efficiency and quality at a higher level. At present, the export market accounts for 70%, and the domestic market accounts for 30%.

2021

In 2021, Company ushered in the peak of foreign trade orders, Purchased More advanced CNC processing equipment, and welcomed unprecedented sales in the domestic market, and participated in the “2021 China International Textile Machinery Exhibition and ITMA Asia Exhibition” in Shanghai as scheduled.

2020

In 2020, the Covid-19 pandemic Caused 2020 ITMA Asia exhibition was postponed, the factory was reduced staffing and manufacture cost to improve product quality, equipment was upgraded to a higher level, and the core team was reorganized to enhance the overall core values.

2019

In 2019, foreign trade sales be expanded, and sales in several important countries and regions increased significantly; And Purchased More advanced CNC processing equipment; Attend the local textile machinery exhibition in Karachi of Pakistan in March of this year, and receive orders and regional agents; In June of the same year, Company participated in the “ITMA Textile Machinery Exhibition” in Barcelona. At the same time, two European agent booths showed Vilike Company machinery and equipment, and formally aligned with European teams to display world-class technical equipment, which shocked western manufacturers; In September of the same year, Company participated in the local textile machinery exhibition in Tashkent, Uzbekistan, Central Asia, and received orders and regional agents; In October of the same year, he participated in the European country tour organized by the China Textile Association and went to advanced industrial countries in Europe, such as Germany and Italy, for in-depth technical Communication exchanging . In November of the same year, the exhibition of “full function computer Separations Jacquard machine” was showed at the “Shanghai International Textile Industry Exhibition” as scheduled, which caused a sensation in the industry.

2018

In 2018, Company participated in “China International Textile Machinery Exhibition and ITMA Asia Exhibition”, and made its first show of exhibition to introduce different machines definition of Asian version and European version to all textile machinery market, which attracted a lot of followers from peers; In the same year, We went to Tehran of Iran, for inspection and Communication.

2017

In 2017, Company expand the production Workshop, employ more high-tech Technician, and expand the production ability and Purchased More advanced CNC processing equipment.

2016

In 2016, Company started to promote regional agents in foreign trade market, and expand production scale and introduce advanced CNC processing equipment.

2015

In 2015, Company participated in ITMA Exhibition in Milan of Italy. For the first time, Vilike Company Products appeared at two European agent booths on the same exhibition Hall. At the same time, he invested in new CNC equipment to expand the production ability.

2014

In 2014, the production ability and staffing were further expanded, and more new CNC machine tools were introduced.

2013

In 2013, Company established and invested in the preparation of Factory and began to manufacture complete machines and spare parts.

Testimonials

Vilike’s single jersey machines are the productivity backbone of our workshop. They run with exceptional stability and low downtime, increasing our output by about 15% compared to our previous equipment. Their after-sales team is responsive, often resolving issues quickly through remote guidance. Highly recommended for peers seeking efficiency and reliability.

Frank McDonald

The double jersey machine we purchased is primarily used for high-end home textile fabrics. Its remarkable precision produces fabrics with clear patterns and superior texture, fully meeting our quality standards. Their technical support team is highly professional, understanding our specific needs and providing effective solutions.

Kelly Miller

As a new customer, we are impressed with the performance of this high-speed electronic jacquard machine. It perfectly adapts to our production needs for high-elasticity sportswear fabrics. The software is intuitive, and pattern changes are efficient. The cost-performance ratio is highly competitive at this price point. We are considering placing additional orders.